The function of the compressor is to lift the pressure and the resulting concentration of the coolant vapor to a sufficiently low level so that the coolant can condense through the condensation by rejecting its heat. Air compressors can be used in a variety of industries and even they are used in small workspaces, garages, and houses for fulfilling various purposes.

Choosing the right air compressor for your use is an important task as there are many brands available in the market delivering the same powered air compressor to the people but you have to go for a review of the Best Air Compressor Brands and choose the best brand among all the competition.

Let’s start with some types of air compressors that are most commonly used by people all around the globe.

Positive Displacement Compressors

A wide range of air compressors that produce energy through air displacement are included with positive displacement compressors. Slightly different functions exist in air compressors in this classification, but each concept is similar. The air carried from outside is removed from a cavity inside the device and gradually condenses the cavity to allow air pressure and kinetic energy. These types are used most commonly in construction sites.

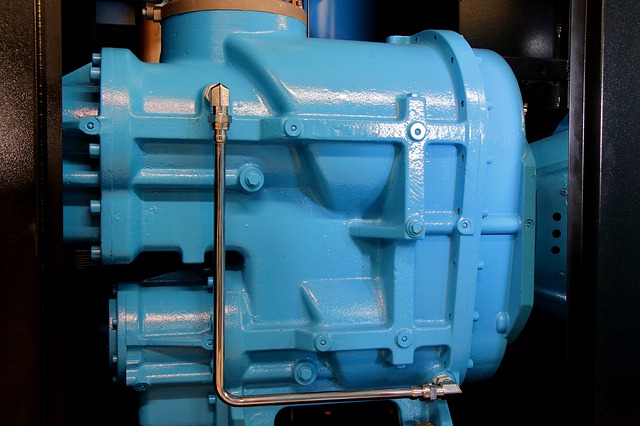

- Rotary Screw Compressors

Air compressors from the rotary screw produce energy from two inner axles rotating in the opposite way. The air is squeezed between both the dual opposite rotors and the tension in the housing rises. The air compressor is equipped for regular use with energy ranges from 5 HP to 350 HP, thanks to the internal cooling system. These are generally large commercial devices, which can be lubricated with oil or without oil. These types of compressors are a type of positive displacement compressor.

- Reciprocating Compressors

Another example of positive displacement compressors, Usually, these are used in smaller workplaces like garages and homes. The reciprocal compressor is not designed to be used continuously unlike the rotary screw compressor. Such air compressors operate through a piston in a cylindrical framework, which compresses and pushes the air into pressure formation. Compressors can be reciprocated in single or multiple stages, affecting the force ranges that they can reach.

Dynamic Compressors

Dynamic air compressor systems generate horsepower by inserting rapidly rotating blades into the air and then reducing the pressure. The potential energy is then stored inside the compressor as stable. These types are used in large chemical and steel Industries and plants for continuous usage.

- Axial Compressors

For construction projects, axial air compressors are typically not used but are instead used in boat or plane in high-speed generators. These have a highly efficient level but are far more costly than most other air compressor models and can handle up to thousands of hp, and are therefore primarily used for aviation analysis.

- Centrifugal Compressors

Centrifugal air compressors pause and refresh the input air via a diffuser to develop kinetic energy. With the multi-phase pressure mechanism, these compressors in a relatively small machine can generate high energy output. Typical for more demanding industrial estates such as industrial plants or steel production centers, they can exceed approximately 1000 HP.